London Lift Company: Giving Comprehensive Lift Solutions Throughout the Funding

London Lift Company: Giving Comprehensive Lift Solutions Throughout the Funding

Blog Article

Checking Out the Diverse Ranges of Lift Solutions and Their Regular Malfunctions

In the realm of upright transportation, lift systems play an essential duty in assisting in the motion of people and items across various frameworks. From hydraulic to grip, pneumatic, and chairlift systems, each type boasts its unique layout and functional qualities. However, similar to any type of mechanical system, lift systems are at risk to breakdowns that can vary from minor aggravations to crucial failings. Comprehending the diverse varieties of lift systems and their regular breakdowns supplies valuable insights into guaranteeing the security and performance of upright transport.

Lift Systems Introduction

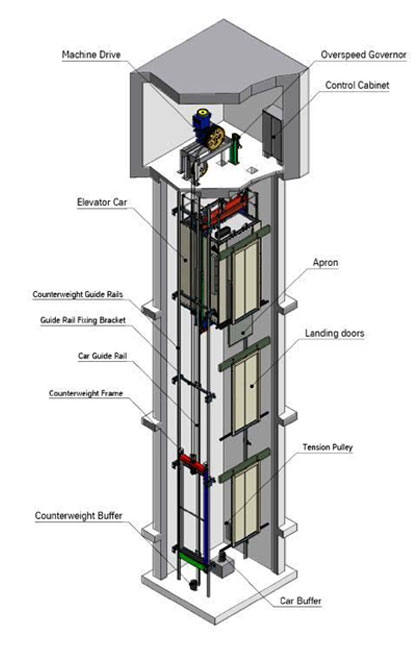

One basic component of modern-day urban infrastructure is the elevator system, essential for upright transportation in buildings of differing elevations. Elevators, also referred to as lifts in some areas, are made to effectively relocate people and goods in between various floors within a structure. These systems include numerous vital elements, including the lift cars and truck, hoisting control, mechanism, and weight systems.

The lift car works as the platform that carries travelers or freight, while the hoisting device, generally made up of chains or ropes, moves the automobile up and down along the elevator shaft. The counterweight assists stabilize the lots of the car, making the system a lot more energy-efficient - lift maintenance contractors. Control systems, such as switches inside the automobile and on each floor, allow customers to select their desired location and operate the lift securely

Hydraulic Lift Equipments

Relocating from the realm of elevator systems summary to a more specialized domain name, hydraulic lift systems provide a distinct approach to vertical transport within structures. These systems are typically found in low to mid-rise structures where the vertical traveling distance is moderate.

One common malfunction of hydraulic lift systems is oil leakage due to worn-out seals or damaged hydraulic hose pipes. Regular maintenance and hydraulic liquid checks can aid prevent these malfunctions and make certain the smooth operation of hydraulic lift systems.

Grip Lift Systems

Exploring the elaborate mechanisms of upright transport, grip lift systems change the method passengers move within high-rise structures (lift maintenance contractors). These systems operate based upon the principle of friction in between the lift vehicle and the hoist ropes, permitting effective vertical activity. Grip lift systems are typically found in modern-day skyscraper structures and are understood for their smooth experiences and energy efficiency

One typical kind of grip system is the tailored traction system, where the lift cars and truck is affixed to the hoist ropes via a gear system. This setup offers outstanding control over the activity of the lift automobile and is appropriate for mid to skyscrapers. Another kind is the gearless grip system, which removes the requirement for an equipment system, making it much more portable and ideal for extremely tall buildings.

Regardless of their efficiency, grip lift systems can experience breakdowns such as rope slippage, motor failures, or problems advice with the control system. Regular upkeep and punctual repair work are vital to make sure the trustworthy and risk-free procedure of grip lift systems in skyscraper structures.

Pneumatic Lift Systems

Pneumatic lift systems utilize atmospheric pressure differentials to assist in upright transportation within buildings. These systems operate by making use of compressed air to move the lift car within a hoistway. As the air stress decreases or increases in the system, the elevator is either raised or decreased as necessary. One of the vital advantages of pneumatic lift systems is their power effectiveness contrasted to conventional traction systems, as they do not call for counterweights or considerable machinery.

However, pneumatically-driven lift systems are not without their common malfunctions. One typical problem is air leak within the system, which can lead to a decline in stress and, as a result, a decrease in lift performance. Furthermore, variants in air temperature can affect the atmospheric pressure and effect the smooth operation of the elevator. Normal maintenance and surveillance of the system's atmospheric pressure levels Resources are important to stop these malfunctions and ensure the reputable operation of pneumatically-driven lift systems.

Chairlift Equipments

In the realm of vertical transportation mechanisms, Chairlift Equipments provide a distinctive choice to the pneumatic lift systems discussed earlier. Chairlift Equipments are frequently used in ski hotels, amusement parks, and other leisure areas to transfer people up and down hillsides or inclines. These systems contain a constantly relocating loop of chairs affixed to a cable television that relocates a constant loop, enabling passengers to disembark and embark at designated factors along the course.

Despite their popularity, Chairlift Equipments are not without their faults. Typical breakdowns include problems with the cable, such as derailments or slippage, which can bring about functional disturbances and safety problems. Mechanical failures in the chairs themselves, such as malfunctioning safety bars or seat locks, can also present threats to guests. Regular maintenance and assessments are important to stop these breakdowns and make sure the risk-free operation of Chairlift Systems. By resolving these regular malfunctions without delay, drivers can keep the effectiveness and dependability of Chairlift Solutions for the individuals who depend on them for transportation and recreation.

Verdict

In final thought, lift systems are necessary for vertical transportation in different structures and frameworks. Hydraulic, traction, pneumatically-driven, and chairlift systems are commonly utilized, each with their very own prospective breakdowns and one-of-a-kind qualities. It is very important for upkeep workers to be experienced about the varied varieties of lift systems and their normal malfunctions to ensure the security and performance of these systems.

As with any type of mechanical system, lift systems are susceptible to breakdowns that can vary from minor inconveniences to essential failures.Relocating from the realm of elevator systems summary to a more customized domain, hydraulic lift systems use a distinctive method to vertical transport within buildings.One usual type of grip system is the tailored traction system, where the lift vehicle is attached to the hoist ropes via a gear system. Routine maintenance her response and surveillance of the system's air pressure levels are crucial to protect against these breakdowns and ensure the trustworthy procedure of pneumatic lift systems.

It is essential for maintenance workers to be educated about the varied selections of lift systems and their common malfunctions to make certain the safety and security and performance of these systems.

Report this page